In today’s market, it’s easy to get caught up in finding the lowest price, but when it comes to heavy equipment attachments, where your gear comes from makes all the difference.

Parts, Tariffs, & Quality

The biggest gap we see between locally sourced, and foreign-built attachments, is after sale support. Trust us, we’ve tried. With many combined years in this industry, we’ve spent countless hours helping customers hunt for parts from overseas brands, often to find the parts simply don’t exist, or will take months to arrive. Meanwhile, North American manufacturers have parts, diagrams, and people who actually answer the phone. That’s support you can count on.

There’s also the growing risk of tariffs and import restrictions. A “good deal” today can quickly turn into a money pit when parts double in price or become unavailable altogether. Local manufacturers aren’t hit the same way, meaning long-term stability and predictable ownership costs.

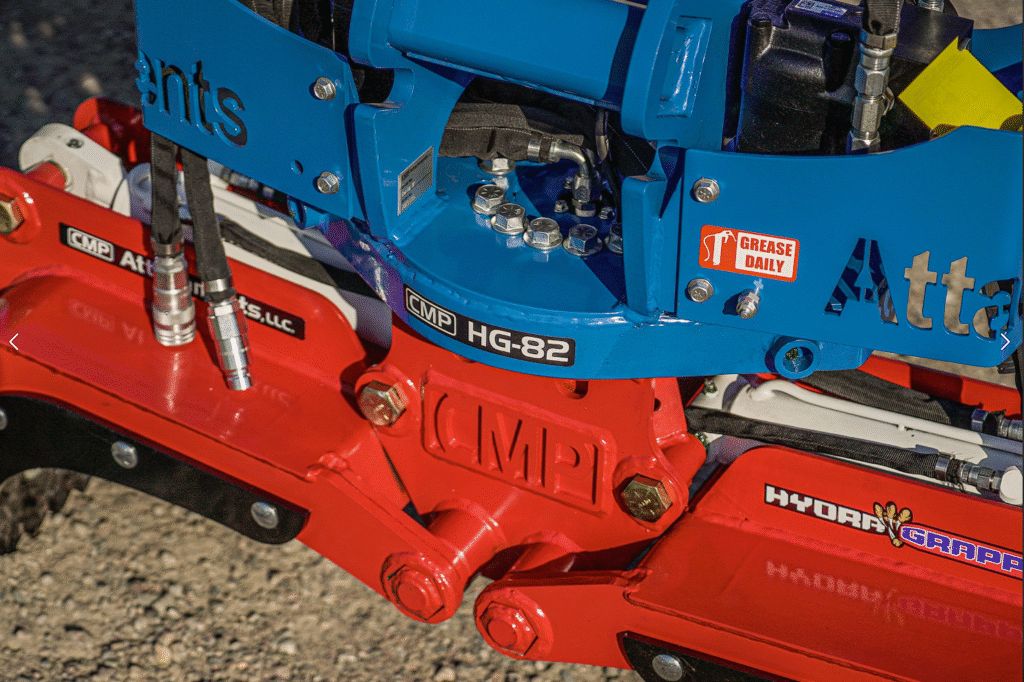

Then there’s the quality behind the welds and materials. In North America and the EU, worker certifications and safety standards are verifiable and regulated. That means welders, machinists, and assembly techs are trained to do it right. Every product passes documented quality control.

Final Thoughts

Finally, it’s about knowing where your dollar goes. Paying a bit more for a locally built attachment doesn’t just buy quality; it supports skilled jobs right here at home. Whether it’s a welder in Missouri, or an assembly technician in North Dakota, you can rest easy knowing your dollar is helping to put a roof over the head of the folks who do the hard work. That’s a difference you can be proud of.

At Forge Attachments, we believe in transparency. Every brand we carry shows where it’s headquartered and manufactured right on our brand page. We work exclusively with U.S., Canadian, and European manufacturers because these regions uphold the highest standards in both quality, and accountability.

https://forgeattachments.com/manufacturers/