Compatibility

At Forge Attachment Co., we ensure our heavy equipment attachments are fully compatible with your machine, guaranteeing optimal performance and efficiency.

Attachment Mount Plates

The connection between your machine and attachment is critical. Ensuring compatibility with your machine’s quick-attach system is essential for seamless operation and efficiency.

Hydraulic Couplers and Flow

Hydraulic power is essential for many attachments. Ensuring compatibility with your machine’s hydraulic system is crucial for safe, efficient, and reliable operation.

Lift Capacity

Lift capacity is a key consideration when selecting attachments. Exceeding your machine’s limits can lead to excessive wear, safety hazards, and reduced productivity.

Skid Steer Electrical Connections

Skid steer attachments with multiple functions require electrical connections to control hydraulic flow and switch between operations efficiently

Attachment Mount Plates, Hydraulic Couplers and Flow, and Lift Capacity

Our attachments are engineered for seamless integration with skid steers, compact track loaders, and mini skid steers. To maximize performance, it’s crucial to consider key compatibility factors, including mount plates, hydraulic couplers and flow, and lift capacity. Below, we outline these essential considerations to help you select the ideal attachment for your machine.

Attachment Mount Plates

The mount plate is the interface that connects your machine to the attachment. It’s crucial to ensure the attachment mount is compatible with your machine’s quick-attach system. Here are the most common options.

To ensure a secure fit, always confirm your machine’s attachment interface before selecting an attachment.

Universal Quick Attach (QA)

Compatible with most major brands (e.g., Caterpillar®, Bobcat®, CASE®), allowing for quick and easy attachment changes. Our attachments are designed to fit machines with this standard.

Mini Skid Steer Universal Mount

Mini Skid Steer Universal Mounts allow quick attachment changes across various mini skid steer models. These mounts offer flexibility and ease of use, making it simple to connect attachments like augers and grapples. Ensure compatibility by checking your machine’s specifications.

Bobcat MT

Mini Bobcat MT plates are designed specifically for Bobcat® MT series mini skid steers, providing a secure and efficient connection for attachments. These plates ensure a perfect fit, allowing for quick attachment changes and optimal performance on smaller, compact machines.

ASV Plate

Mini ASV plates are designed for ASV® mini skid steers, offering a secure and reliable connection for various attachments. These plates ensure compatibility, allowing for quick and easy attachment changes, enhancing the versatility and performance of your mini skid steer.

Excavator Pin-On Mounts

Excavators with pin grabber systems are easy to recognize but require precise measurements to ensure proper fitment. Since machine models, like the Takeuchi TB135, may not always have a standard mount, variations can occur due to dealer-installed or aftermarket couplers. To assist customers in confirming compatibility, we provide a simple diagram for accurate measurement and verification.

Excavator Wedge Lock Mounts

Excavator Wedge Lock Mounts use a wedge-shaped lock for a secure, stable connection and quick attachment changes. Fitment can vary, so contact our sales team at sales@forgeattachments.com for assistance. For example, a Takeuchi TB135 may not always have a standard mount, as dealers sometimes replace couplers with aftermarket ones.

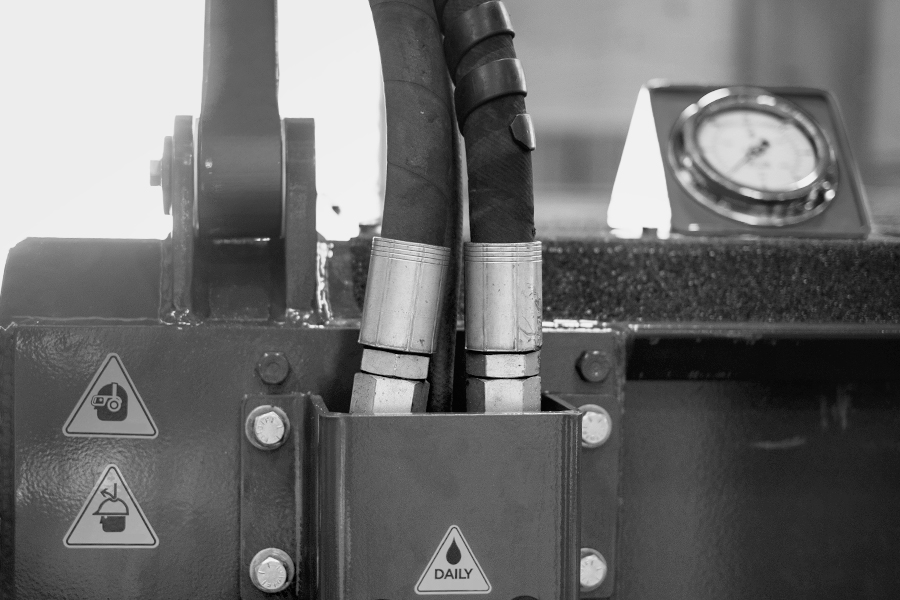

Hydraulic Couplers and Flow

Many of our attachments require hydraulic power for operation, so ensuring compatibility with your machine’s hydraulic system is essential for safe and efficient use. Pay attention to the following hydraulic considerations:

– Verify that the coupler type on your machine matches the one required by the attachment. We also offer adapters for non-standard couplers.

– Check the hydraulic flow capacity of your machine and ensure it aligns with the flow rate required by the attachment.

Taking these steps will help ensure smooth, reliable performance.

Standard Flat-Faced Couplers

These are widely used and ensure a secure, leak-free connection. These come in sizes of ½”, 5/8”, and ¾” for the input and output of powered flow, as well as 3/8” fittings for case drains (bleed off lines).

Pioneer® and other Brands

Attachments designed for specific coupler systems such as Pioneer® or others commonly used in the industry in older machinery and farm equipment.

Hydraulic Flow Rate

Attachments that require hydraulic power typically have specific flow rate requirements (measured in GPM – gallons per minute). Common flow rate categories include:

- Low Flow (Up to 12 GPM): Suitable for lighter attachments such as augers, grapple buckets, or sweepers.

- Standard Flow (12-25 GPM): Common for a variety of attachments, including augers, pallet handlers, and compactors.

- High Flow (25+ GPM): Required for larger or high-demand attachments like mulchers, snow blowers, or cold planers.

Lift Capacity

Your machine’s lift capacity is a key factor when selecting attachments. Exceeding the rated capacity can lead to excessive wear, safety hazards, and decreased productivity. Always ensure that the combined weight of your attachment and the load it will carry stays within your machine’s rated lift capacity.

Each attachment is designed to operate within a specific weight range. Consider the following guidelines to ensure lift capacity compatibility.

Machines have varying lift capacities, typically listed in the operator’s manual or on the machine’s data plate. Always compare your machine’s rated operating capacity (ROC) with the weight of both the attachment and the load.

Light Duty Machines:

– Best for low to moderate weight attachments, such as landscape rakes, soil conditioners, or smaller buckets.

– Medium Duty Machines: Designed for mid-weight attachments like trenchers, augers, or large pallet forks.

– Heavy Duty Machines: Built for larger, heavier attachments, including mulchers, planers, and heavy buckets.

Weight of the Attachment

Make sure that the weight of the attachment, when fully loaded, is within the lift capacity of your skid steer or mini skid steer. Always account for the weight of the attachment itself in addition to the load it will carry.

Lift Capacity of Your Equipment

Machines come with varying lift capacities, which can be found in your operator’s manual or on the machine’s data plate. Be sure to compare the machine’s rated operating capacity (ROC) to the weight of the attachment and the load being handled.

- Light Duty Machines: Ideal for attachments with low to moderate weight, such as landscape rakes, soil conditioners, or smaller buckets.

- Medium Duty Machines: Can handle mid-weight attachments such as trenchers, augers, or large pallet forks.

- Heavy Duty Machines: Suited for larger, heavier attachments, including mulchers, planers, and heavy buckets.

Skid Steer Electrical Connections

Attachments like snowblowers, brooms, and mixers require an electrical connection, while attachments such as augers, grapples, and pallet forks do not. Not all skid steers are equipped with an electrical connection, as it is often an optional add-on from the dealership. Therefore, it is crucial to verify your machine’s electrical capabilities before purchasing an attachment.

14-Pin Skid Steer Electrical Connection

The most common electrical connection available used by the majority of skid steer manufacturers including Cat, Case, Kubota, etc.

Note: When identifying your connection – it is important to count the number of available holes, not active pins.

8-Pin Skid Steer Electrical Connection

Common between ASV and Terex machines between approximate years of 2000-2014. Still remains an option from the factory for ASV.

Note: When identifying your connection – it is important to count the number of available holes, not active pins.

7-Pin Bobcat Skid Steer Electrical Connection

Only seen in Bobcat skid steers. These connectors are unique to their machines and allow for advanced computerized functionality of attachments. Bobcat machines older than approximately 2010 have the potential of being equipped with a 14-pin connector and must be checked.

Note: When identifying your connection – it is important to count the number of available holes, not active pins.

Switch Controllers

These controllers are used when a machine does not have an electrical connection installed on their machine. Based off the manufacturer is a rocker or toggle switch that will need to be plumbed into 12v electrical of the machine.

Electrical power is pulled from a cigarette lighter, unused wiper blade, or any other 12v source available from the machine.

Frequently Asked Questions (FAQ)

How do I know if an attachment is compatible with my machine?

Compatibility depends on several factors, including the attachment mount plate, hydraulic couplers and flow, and your machine’s lift capacity. First, check the type of mount system your machine uses (e.g., Universal Quick Attach, Bobcat®, John Deere®) and make sure the attachment has the corresponding mount plate. Next, verify that your machine’s hydraulic system can provide the correct flow rate and match the coupler type required by the attachment. Finally, ensure that the weight of the attachment and the load being carried does not exceed your machine’s rated lift capacity. If you’re unsure, our team can assist with compatibility checks.

What is the difference between Universal Quick Attach and brand-specific mount plates?

Universal Quick Attach (QA) is a standardized system found on most skid steers and compact track loaders, allowing for quick and easy attachment changes. Brand-specific mount plates are designed to fit the proprietary attachment systems of specific manufacturers like Bobcat®, John Deere®, and CASE®. If you have a machine with a brand-specific mount, you’ll need to select an attachment with the corresponding mount plate for a proper fit.

How can I tell if my machine uses standard or high-flow hydraulics?

All machines have standard flow but the question is if you have the high flow option installed on that machine. You can find your machine’s hydraulic flow rate in its operator’s manual or on the machine’s data plate. Standard flow typically ranges between 12-25 GPM (gallons per minute), while high-flow systems usually exceed 25 GPM. It’s important to match the hydraulic flow requirement of the attachment with your machine’s output to ensure proper operation. If you’re unsure, we can help you verify your machine’s specifications.

What types of hydraulic couplers are available?

We offer attachments compatible with several types of hydraulic couplers, including:

- Standard Flat-Faced Couplers: Common and widely used for a secure, leak-free connection.

- Pioneer® and other coupler types: Designed for specific systems like Pioneer® or other industry-standard couplers are available upon request.

Make sure the hydraulic coupler type on your machine matches the one required by your attachment. We also offer adapter options if necessary.

What happens if the attachment is too heavy for my machine?

If the attachment exceeds your machine’s lift capacity, it can result in reduced performance, excessive wear on your equipment, and safety hazards. Always check the rated operating capacity (ROC) of your machine, which can be found in your operator’s manual or on the machine’s data plate. The weight of the attachment plus the load should never exceed this limit.

Can I use attachments across different brands of machines?

Many attachments are designed to be cross-compatible with multiple brands, especially those using the Universal Quick Attach system. However, brand-specific systems require the corresponding mount plate designed for that brand. If your machine uses a unique mounting system or has different hydraulic coupler requirements, we can help you find an attachment that fits or recommend adapters.

What is the importance of matching hydraulic flow rates?

Hydraulic flow rate is essential for powering attachments that require hydraulic fluid for operation. If the flow rate of your machine doesn’t match the attachment’s requirements, the attachment may not function properly or could be damaged. Attachments are typically designed for low, standard, or high hydraulic flow. Be sure to check your machine’s flow rate and select an attachment that falls within the compatible range.

Do you offer custom mounting options?

Yes, if your machine has a unique mounting system or specific requirements, we can work with you to provide custom mounting options to ensure proper fit and functionality. Please contact our customer service team with your machine details for more information. Lead times, cost, and manufacturing workload may affect this.

How do I determine the right attachment for my machine’s lift capacity?

Check your machine’s rated operating capacity (ROC), which can be found in your operator’s manual or on the machine’s data plate. Choose attachments that are within the weight limits of your machine’s ROC to ensure safe and efficient operation. Always consider the weight of the attachment itself plus any load it will carry, and avoid exceeding your machine’s lift capacity.

What should I do if I am still unsure about compatibility?

If you’re unsure about compatibility, don’t hesitate to reach out to our expert team. We can help verify if an attachment will work with your machine based on its mount plate, hydraulic couplers and flow, and lift capacity. Provide us with your machine’s make, model, and specifications, and we’ll assist you in choosing the right attachment.

Give us a call. We’re here to help.

For more detailed questions or to speak with a compatibility expert, contact our sales team at sales@forgeattachments.com or 1-866-378-0219.